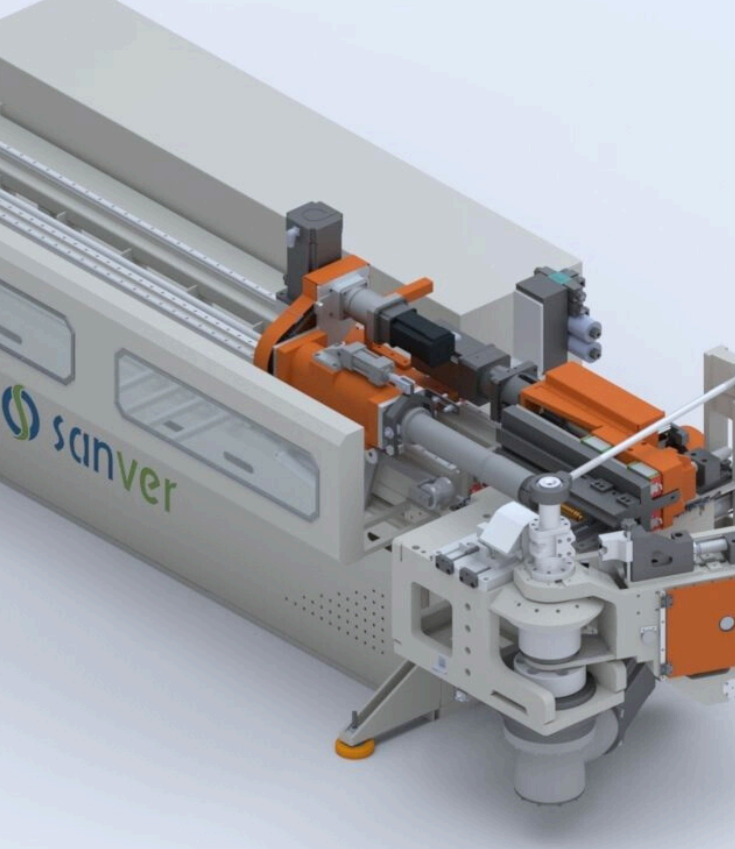

CNC Pipe Bending

- Feeding

- Rotation

- Bending

- Horizontal movement of the bending head

- Pressure applied to the pipe surface

Each axis operates independently with precise speed control, ensuring perfect synchronization of simultaneous movements. This ensures high-precision results in both simple and complex bending operations.

Operator-Focused Features

Portable Control Unit: Easy use and system management thanks to the movable control panel.

Protective cabin structure: Specially designed cabinets to protect electrical components and ensure safe and long-lasting use.

Integrated security infrastructure: System infrastructure ready for safety mat connections for operator safety.

Key Features

Five-axis, independent servo-controlled motion system

High reliability and low maintenance with chainless drive structure

Possibility of bending pipes with single or multiple bending molds

Independent pressing mechanism for each bending die

High transmission performance with mechanical efficiency over 90%

High bending accuracy with a sensitivity range of ±0.05° to ±0.1°

Optimized operating system with minimum interference in the operating area

User-friendly CAD/CAM programming infrastructure with 3D simulation support

Bending Capacities According to Models

| Model | Twisting Capacities |

|---|---|

| SnrTB01 | Ø19 mm |

| SnrTB02 | Ø30 mm |

| SnrTB03 | Ø38.1 mm |

| SnrTB04 | Ø50.8 mm |

| SnrTB05 | Ø63.5 mm |

| SnrTB06 | Ø88.9 mm |

| SnrTB07 | Ø101.6 mm |

| SnrTB08 | Ø127 mm |

User-Friendly CAD/CAM Software

Fast program selection with extensive parts library with advanced filtering features

3D simulation support to validate designs before production

Easy and safe programming process with automatic error correction and guided design tools

Operators can easily select previously saved programs or create new part definitions;

All bending parameters are applied accurately. The user-friendly interface allows even less experienced operators to achieve professional-level results.

Efficiency and Reliability

Safe Automatic Operation:

Advanced sensors prevent waste by automatically stopping production under unfavorable conditions and provide stable production performance that ensures continuity.

Precision from the First Piece:

Regardless of the shape or material of the pipe, the system offers repeatability and geometric accuracy on every part.

Quick Tool Change:

Thanks to quick change systems, tools can be changed within 3 minutes, minimizing downtime and allowing production to continue uninterrupted.

Türkçe

Türkçe

English

English

ile hazırlanmıştır.

ile hazırlanmıştır.