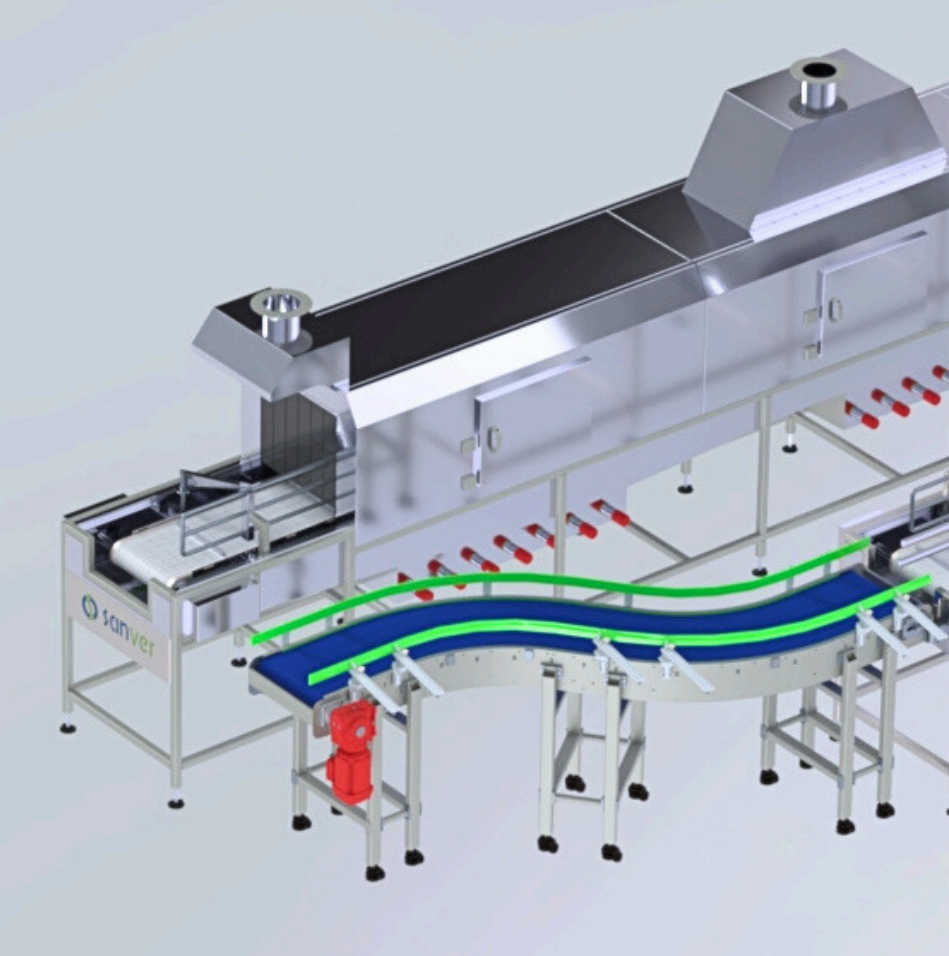

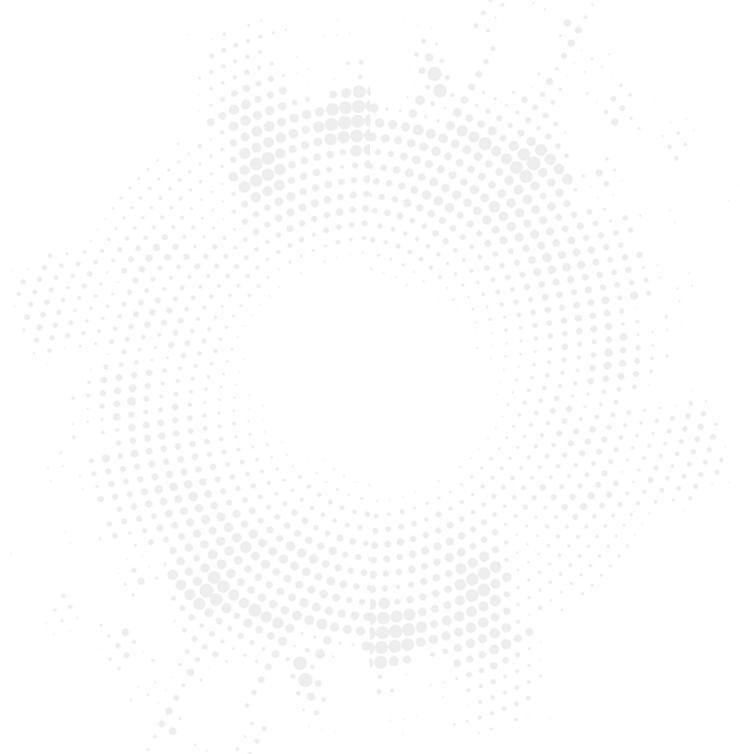

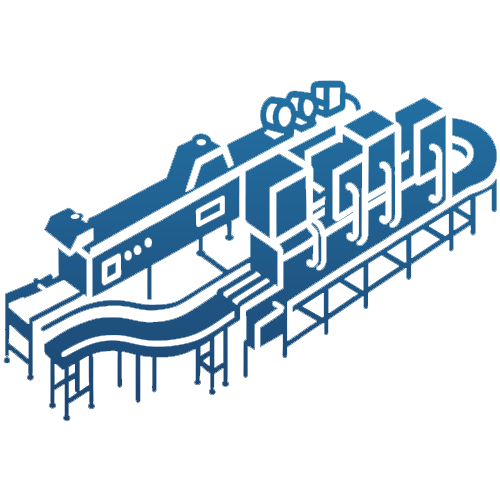

Industrial Washing System

This system, widely used in the automotive, foundry, and metalworking industries, effectively removes dirt, sawdust, oil, and chemical residue from parts. Thanks to its conveyor structure, the system automatically performs washing and drying processes as parts move uninterrupted through the production line.

Features

Design suitable for continuous flow

High efficiency and cleaning performance

Low water and energy consumption

Structure compatible with different part sizes and geometries

The system features a multi-stage washing system that can be configured to suit product requirements. Each module operates independently, with its own circulation line and filtration system.

In general, the line consists of the following stages:

Pre-Wash: Removal of coarse dirt and chips on the part

Ana Yıkama: Intensive cleaning with hot water and chemical support

Rinse: Removal of chemical residues with clean water

Drying: Fast drying with high flow blower or hot air system

Each stage is equipped with a dedicated pump and tank system.

Temperature and water level are controlled automatically.

The number of modules can be increased according to customer demands.

Technical Specifications

| Property Value | Value |

|---|---|

| Washing Capacity | Determined by material and part. |

| Conveyor Type | Stainless steel wire / Plastic modular belt* |

| Body Material | AISI 316* |

| Heating Type | Electric* |

| Washing Temperature | 60 – 75 °C * |

| Number of Tanks | 3 – 5 * |

| Control System | PLC + Touch Panel* |

| Drying System | Hot air / High capacity blower* |

| Water Recovery | Multi-stage filtration system* |

* (Determined depending on the process.)

REFERENCE PROJECTS

VALEO

Project: Tunnel Type Industrial Washing System

Application: Tunnel type fully automatic washing and drying system for automotive powertrain parts

Location: Germany

PHINIA

Project: Cabin Type Washing System

Application: Cyclic washing of sensitive fuel system components in a compact cabin

Location: Türkiye

STELLANTIS

Project: Vehicle Dynamic Sealing Test Facility

Application: Fully automatic dynamic water tightness testing system under high pressure on complete vehicles

Location: Türkiye

TOGG

Project: Vehicle Dynamic Sealing Test Facility

Application: Robot-controlled automatic dynamic water tightness testing system for domestic electric vehicles

Location: Türkiye

TOGG

Project: Vehicle Static Sealing Test Facility

Application: Sensor-supported leakage verification cabin with constant pressure water spray system

Location: Türkiye

Türkçe

Türkçe

English

English

ile hazırlanmıştır.

ile hazırlanmıştır.